Products

Condensate Recovery Back to all Condensate Recovery

- In this category:

- W4100, W4200, W4300

- W4100, W4200, W4300

- PMPC

- PMPF

- PMPSS

- PMPLS

- PMPBP

- PMPNT

- PMPNTS

- PMPM

- PMPSP

- PMPT

- PMPTS

- WPT3

- WPT4-WPT5

- PMPC

- PMPNT

- PMPBP

Electric Boiler Feed Pumps

W4100, W4200, W4300

Specifications

| Model | W4100 |

| Discharge Pressure | 20 – 50 PSIG |

| Motor HP | 1/3 – 2 |

| Pump Receiver Tank Material | Carbon Steel |

| Flow Rate GPM | 3-6 |

| Boiler HP | 15-30 |

| Receiver Capacity | 30 gallons |

|

|

|

| Model | W4200 |

| Discharge Pressure | 20 – 50 PSIG |

| Motor HP | 1/3 – 2 |

| Pump Receiver Tank Material | Cast Iron |

| Flow Rate GPM | 3-6 |

| Boiler HP | 15-30 |

| Receiver Capacity | 36 gallons |

|

|

|

| Model | W4300 |

| Discharge Pressure | 20 – 50 PSIG |

| Motor HP | 1/3 – 2 |

| Pump Receiver Tank Material | Stainless Steel |

| Flow Rate GPM | 3-9 |

| Boiler HP | 15-45 |

| Receiver Capacity | 30 gallon – 45 Gallon |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The Boiler Feed Pumps (W4300 series) are equipped with Cast Iron bodies and Bronze Impellers. The pump receiver tank is made of Stainless Steel and available in Simplex or Duplex configurations. Energy efficient 3450 RPM motors, automatic venting of mechanical seal, ceramic pump seal with carbon face, heavy duty float switch.

Options: Mechanical and electrical alternators, gauge glass, thermometers, discharge pressure gauges, isolation valves, magnetic starters with HOA selector switch, 1750 RPM motors, larger pumping capacities & higher discharge pressures, wide variety of SSI control panels, oversized receivers (45,60 & 95 gallons)

Notes:

- EDR square feet of Equivalent Direct Radiation

- Capacity of steam (1lbs/hr) = EDR x 0.25

- 2,000 EDR will produce 500 lbs/hr of condensate

- 500 lb/hr = GPM

Electric Condensate Return Pumps

W4100, W4200, W4300

Specifications

| Model | W4100 |

| Discharge Pressure | 20 PSIG |

| Motor HP | 1/3 – 2 |

| Pump Receiver Tank Material | Carbon Steel |

| Flow Rate GPM | 3-75 |

| Receiver Capacity | 15 – 95 Gallon |

|

|

|

| Model | W4200 |

| Discharge Pressure | 20 PSIG |

| Motor HP | 1/3 – 2 |

| Pump Receiver Tank Material | Cast Iron |

| Flow Rate GPM | 3-75 |

| Receiver Capacity | 6 – 50 Gallon |

|

|

|

| Model | W4300 |

| Discharge Pressure | 20 PSIG |

| Motor HP | 1/3 – 1 |

| Pump Receiver Tank Material | Stainless Steel |

| Flow Rate GPM | 3-45 |

| Receiver Capacity | 15 – 45 Gallon |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The Condensate Return Pumps (W4300 series) are equipped with Cast Iron bodies and Bronze Impellers. The pump receiver tank is made of Stainless Steel and available in Simplex or Duplex configurations. Energy efficient 3450 RPM motors, automatic venting of mechanical seal, ceramic pump seal with carbon face, heavy duty float switch.

Options: Mechanical and electrical alternators, gauge glass, thermometers, discharge pressure gauges, isolation valves, magnetic starters with HOA selector switch, 1750 RPM motors, larger pumping capacities & higher discharge pressures, wide variety of SSI control panels, oversized receivers (45,60 & 95 gallons)

Notes:

- EDR square feet of Equivalent Direct Radiation

- Capacity of steam (1lbs/hr) = EDR x 0.25

- 2,000 EDR will produce 500 lbs/hr of condensate

- 500 lb/hr = GPM

Pressure Motive Pump

PMPC

Specifications

| Model | PMPC |

| Connections | 1’’ x 1’’ to 3’’ x 2’’ |

| Tank Material | Cast Ductile Iron |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 388°F |

| PMA (Max Allowable Pressure) | 200 PSIG @ 650°F |

| TMA (Max. Allowable Temperature) | 650°F @ 200 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPC pressure motive pump body & cover are manufactured from ductile iron. ASME “UM” code stamp is available. This pump is typically used when liquids must be moved to a higher elevation, higher pressure or extended distances

Pressure Motive Pump

PMPF

Specifications

| Model | PMPF |

| Connections | 1’’ x 1’’ to 3’’ x 2’’ |

| Tank Material | Carbon Steel |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 388°F |

| PMA (Max Allowable Pressure) | 250 PSIG @ 650°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPF pressure motive pump body & cover are manufactured from carbon steel. These tanks are fabricated with 1/8” corrosion allowance and receive the ASME “UM” code stamp. This pump is typically used when liquids must be moved to higher elevation, higher pressure or extended distances.

Pressure Motive Pump

PMPSS

Specifications

| Model | PMPSS |

| Connections | 1’’ x 1’’ to 3’’ x 2’’ |

| Tank Material | 304L Stainless Steel |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 650°F |

| Note: | For special 316 stainless steel construction; consult factory |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPSS pressure motive pump body & cover are manufactured from 304L Stainless Steel. These pumps receive the ASME “UM” code stamp. This pump is designed to be used in harsh and corrosive environments.

Pressure Motive Pump

PMPLS

Specifications

| Model | PMPLS |

| Connections | 1’’ x 1’’ to 1-1/2’’ x 1-1/2’’ |

| Tank Material | Carbon Steel |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 650°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPLS pressure motive pump body & cover are manufactured from Carbon Steel. These pumps receive the ASME “UM” code stamp. This pump is designed to be used in harsh and corrosive environments. The PMPLS model Carbon Steel non-electric pressure motive pump is a lower profile than the standard PMPF model.

Pressure Motive Pump

PMPBP

Specifications

| Model | PMPBP |

| Connections | 4’’ x 4’’ |

| Tank Material | Carbon Steel |

| Mechanism and Check Valve Material | Stainless Steel & Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 470°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPBP model non-electric Carbon Steel pressure motive pump is extremely high capacity for applications requiring large transfer of condensate or other liquids. This stand-alone pump is capable of operating with a maximum motive pressure of 150 PSIG provided by steam, air, nitrogen, or other pressurized gases as the motive force. ASME “U” Code Stamp available upon request

Pressure Motive Pump

PMPNT

Specifications

| Model | PMPNT |

| Connections | 1’’ x 1’’ to 1-1/2’’ x 1-1/2’’ |

| Tank Material | Ductile Iron |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 450°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPNT non-electric pressure motive pumps are light in weight and have an extremely low-profile. This stand-alone pump is capable of operating with a maximum motive pressure of 125 PSIG provided by steam, air, nitrogen, or other gas supply. ASME Code Stamp available upon request.

Pressure Motive Pump

PMPNTS

Specifications

| Model | PMPNTS |

| Connections | 1’’ x 1’’ to 1-1/2’’ x 1-1/2’’ |

| Tank Material | Stainless Steel |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 650°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPNT(S) non-electric pressure motive pumps are light in weight and have an extremely low-profile. This stand-alone pump is capable of operating with a maximum motive pressure of 125 PSIG provided by steam, air, nitrogen, or other gas supply. ASME Code Stamp available upon request.

Pressure Motive Pump

PMPM

Specifications

| Model | PMPM |

| Connections | 1’’ x 1’’ to 1-1/4’’ x 1-1/4’’ |

| Tank Material | Cast Iron |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 450°F |

| Motive Pressure | 25 – 150 PSIG |

| Back Pressure | 5 – 100 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The Model PMPM pressure motive pump has an extremely low profile. These low-profile tanks are required when draining condensate from process equipment positioned close to the ground which limits the filling head of the pump.

Sump Pump Drainer

PMPSP

Specifications

| Model | PMPSP/PMPSPL |

| Connections | 1-1/2’’ to 2’’ |

| Body Material | Carbon Steel |

| Cover Material | Ductile Iron |

| Mechanism and Check Valve Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max Allowable Pressure) | 150 PSIG @ 650°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPSP Sump Drainer uses the same internal mechanism as the standard PMP models. The piping configuration is such that the liquid is discharged vertically out the top as opposed to horizontally out the side. This allows the unit to be easily positioned inside of a sump area. Condensate or water from the sump enters the tank through a stainless-steel low resistance check valve. This unit is capable of operating with a maximum motive pressure of 150 PSIG using steam, air, nitrogen or other pressurized gas as the motive force.

Condensate Packages [Pressure Powered Pump & Trap]

PMPT

Specifications

| Model | PMPT |

| Body Material | Ductile Iron |

| Cover Material | Stainless Steel |

| Sizes | 1’’, 1-1/2’’ NPT |

| Check Valves | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 450°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPT low-profile pressure motive pump & trap combination has an internal steam trap for draining heat exchangers and other equipment whose steam pressure is modulated by a temperature regulator or a temperature control valve. In these applications the steam pressure in the heat exchanger may not be sufficient to overcome the back pressure in the condensate return line. When this condition occurs, the pressure powered pump takes over and uses high pressure steam supplied to the pump to discharge the condensate. When sufficient pressure does exist, the PMPT functions like a standard steam trap. Its small compact design is perfect for applications with limited space.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

Condensate Packages [Pressure Powered Pump & Trap]

PMPTS

Specifications

| Model | PMPTS |

| Body Material | Stainless Steel |

| Cover Material | Stainless Steel |

| Sizes | 1-1/2’’ FLG |

| Check Valves | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 450°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPTS low-profile pressure motive pump & trap combination has an internal steam trap for draining heat exchangers and other equipment whose steam pressure is modulated by a temperature regulator or a temperature control valve. In these applications the steam pressure in the heat exchanger may not be sufficient to overcome the back pressure in the condensate return line. When this condition occurs, the pressure powered pump takes over and uses high pressure steam supplied to the pump to discharge the condensate. When sufficient pressure does exist, the PMPT functions like a standard steam trap. Its small compact design is perfect for applications with limited space.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

Condensate Packages [Pressure Powered Pump & Trap]

WPT3

Specifications

| Model | WPT3 | |

| Pump | Trap | |

| Body | Carbon Steel | Ductile Iron |

| Cover | Carbon Steel | Ductile Iron |

| Cover Gasket | Garlock | Garlock |

| Ball Float | 304 SS | 304 SS |

| Check Valves | 316 SS | n/a |

| Springs | Inconel-X-750 | n/a |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPT Pump-Trap Combinations are excellent for draining condensate from heat exchangers and other equipment whose steam pressure is modulated by a temperature regulator or a temperature control valve. In these applications the steam pressure in the heat exchanger may not be sufficient to overcome the back pressure in the condensate return line. When this condition occurs, the pressure powered pump takes over and uses high pressure steam supplied to the pump to discharge the condensate. When sufficient pressure does exist, the WPT functions like a standard steam trap.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

Condensate Packages [Pressure Powered Pump & Trap]

WPT4-WPT5

Specifications

| Model | WPT4, WPT5 | |

| Pump | Trap | |

| Body | Ductile Iron | Ductile Iron |

| Cover | Ductile Iron | Ductile Iron |

| Cover Gasket | Garlock | Garlock |

| Ball Float | 304 SS | 304 SS |

| Check Valves | 316 SS | n/a |

| Springs | Inconel-X-750 | n/a |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPT Pump-Trap Combinations are excellent for draining condensate from heat exchangers and other equipment whose steam pressure is modulated by a temperature regulator or a temperature control valve. In these applications the steam pressure in the heat exchanger may not be sufficient to overcome the back pressure in the condensate return line. When this condition occurs, the pressure powered pump takes over and uses high pressure steam supplied to the pump to discharge the condensate. When sufficient pressure does exist, the WPT functions like a standard steam trap.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

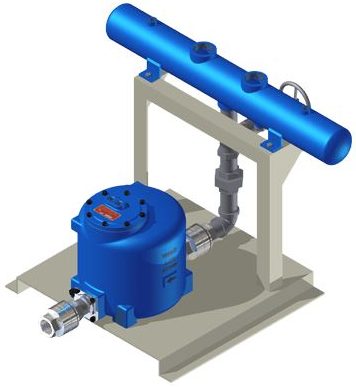

Condensate Packages [Pressure Powered Pump]

PMPC

Specifications

| Model | PMPC Packaged System |

| Package Options | Simplex, Duplex, Triplex |

| Pump Body Material | Ductile Iron |

| Connections | 1”, 1.5”, 2”, 3”, NPT, 150 FL, 300 FL |

| Check Valves | 316 Stainless Steel |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 388°F |

| PMA (Max. Allowable Pressure) | 200 PSIG @ 650°F |

| Receiver Pressure Rating | 150 PSIG @ 566°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPC series (cast ductile iron pump body material) with a Vented Receiver. Standardized Simplex, Duplex, Triplex, and Quadraplex packaged systems include stand-alone pump(s), check valves and vented receiver, mounted on a steel base and frame. Multiple pumping units can be used for increased capacity or for system redundancy. The PMP units are available in ductile iron, carbon steel and stainless steel. Additional options include sight glasses, insulation jackets, cycle counters, motive and vent piping, pressure regulators, steam traps, strainers, ASME code stamps, etc.

Includes: Heavy-duty Pump, Steel Receiver, Isolation Valve(s), SS Check Valves, available in Schedule 40 and 80 Piping, and mounted on a Steel Base.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

Condensate Packages [Pressure Powered Pump]

PMPNT

Specifications

| Model | PMPNT |

| Body Material | Ductile Iron |

| Cover Material | Stainless Steel |

| Sizes | 1’’, 1-1/2’’ NPT |

| Check Valves | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 450°F |

|

|

|

| Model | PMPNTS |

| Body Material | Stainless Steel |

| Cover Material | Stainless Steel |

| Sizes | 1-1/2’’ FLG or NPT |

| Check Valves | Stainless Steel |

| PMO (Max. Operating Pressure) | 125 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 450°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPNT series (cast ductile iron pressure motive pump) with a Vented Receiver. Standardized Simplex, Duplex, Triplex, and Quadraplex packaged systems include stand-alone pump(s), check valves and vented receiver, mounted on a steel base and frame. Multiple pumping units can be used for increased capacity or for system redundancy. The PMP units are available in ductile iron, carbon steel and stainless steel. Additional options include sight glasses, insulation jackets, cycle counters, motive and vent piping, pressure regulators, steam traps, strainers, ASME code stamps, etc.

Includes: Heavy-duty Pump, Steel Receiver, Isolation Valve(s), SS Check Valves, available in Schedule 40 and 80 Piping, and mounted on a Steel Base.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.

Condensate Packages [Pressure Powered Pump]

PMPBP

Specifications

| Model | PMPBP Packaged System |

| Package Options | Simplex, Duplex, Triplex |

| Pump Body Material | Carbon Steel |

| Receiver Material | Carbon Steel |

| Check Valves | Stainless Steel & Steel |

| PMO (Max. Operating Pressure) | 150 PSIG |

| TMO (Max. Operating Temperature) | 366°F |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 470°F |

| Size/Connection | 4’’ x 4’’ 150# FLG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PMPBP series (High capacity carbon steel pressure motive pump) with a Vented Receiver. Standardized Simplex, Duplex, Triplex, and Quadraplex packaged systems include stand-alone pump(s), check valves and vented receiver, mounted on a steel base and frame. Multiple pumping units can be used for increased capacity or for system redundancy. The PMP units are available in ductile iron, carbon steel and stainless steel. Additional options include sight glasses, insulation jackets, cycle counters, motive and vent piping, pressure regulators, steam traps, strainers, ASME code stamps, etc.

Includes: Heavy-duty Pump, 280 Gallon Steel Receiver, Isolation Valve(s), SS Check Valves, available in Schedule 40 and 80 Piping, and mounted on a Steel Base.

SSI Services can provide our customers with a wide variety of sizes, materials, and specifications for our prefabricated packages. We work with our customers to provide custom solutions for almost any application through our unmatched customer service and support in the installation and maintenance of our products.