Products

Heat Tracing Back to all Heat Tracing

- In this category:

- FTS [Fluid Steam Tracing]

- LITE [Light Steam Tracing]

- FPX [Freeze Protection]

- CST [Freeze Protection]

- FJH [Electric Heating Jacket]

- QFX [Fabricated Jackets]

- QFIN [Tank Heating System]

- QCB [Standard Coil Bank]

- FTS [Fluid Tracing System]

- CST [Carbon Steel Tracing]

Steam Tracing

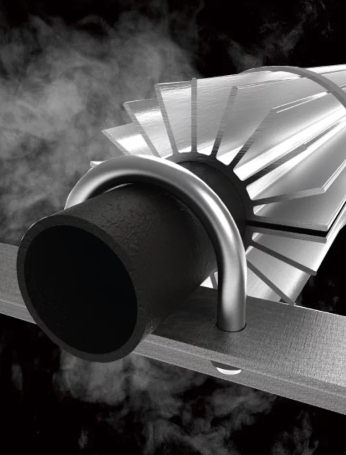

FTS [Fluid Steam Tracing]

Specifications

| Model | QMax FTS Gen 2 |

| For Critical Heat Applications | >180°F (82°C) |

| Material | 6063-T6 Aluminum |

| Thermal Conductivity | ~1390 BTU/hr ft^2 °F (~209 W/m-°K) |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~0.60 lb/ft (0.82 kg/m) |

| Standard tube/pipe size | 3/8’’ – 5/8’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

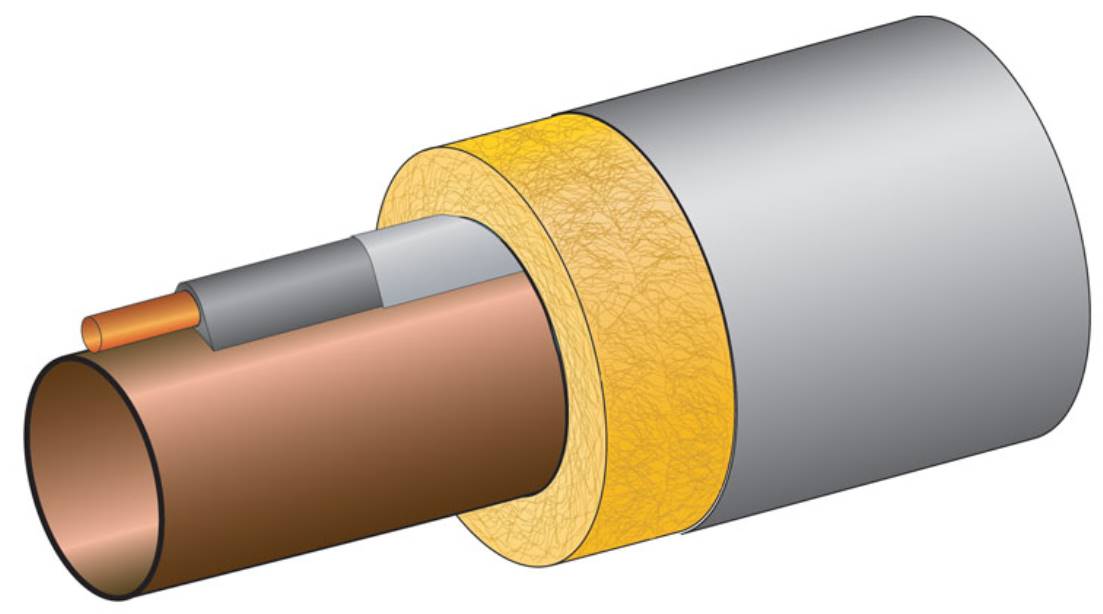

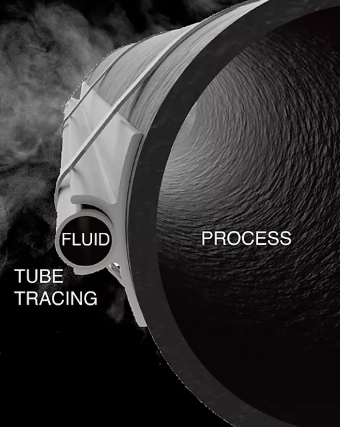

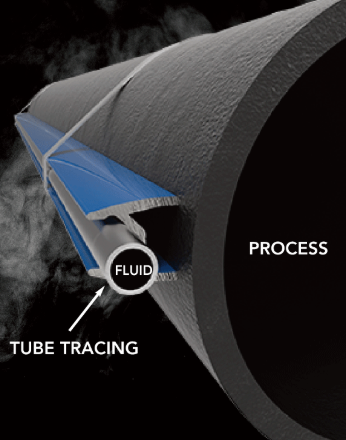

QMax FTS Gen 2 heat tracing maximizes the heat input of regular stainless steel or copper tube tracer and offers consistent results. First, QMax transforms the nature of a steam tracer from ineffective convective heat transfer to highly efficient conductive heat transfer. Second, the heating surface area is increased to as much as 2 inches (50mm) using highly conductive aluminum. A single tracer with the addition of QMax FTS can achieve the same results as multiple tube tracers or even jacketed pipe. This saves time and money on capital projects and reduces long-term maintenance costs.

Steam Tracing

LITE [Light Steam Tracing]

Specifications

| Model | QMax Lite |

| For Medium Heat Applications | 60°F – 180°F (16°C – 82°C) |

| Material | 6063-T6 Aluminum |

| Thermal Conductivity | ~1390 BTU/hr ft^2 °F (~209 W/m-°K) |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~0.60 lb/ft (0.82 kg/m) (without tubing) |

| Standard tube/pipe sizes | 3/8’’ – 5/8’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The QMax Lite Heat Tracing design maximizes the heat input of regular stainless steel or copper tube tracer and offers guaranteed results. QMax LITE is designed for light-duty steam tracing and most glycol tracing applications. QMax LITE transforms the nature of the tracer from inefficient convective heat transfer to high-efficiency conductive heat transfer. The heating surface area is increased to as much as 1.5 inches (38mm) using highly conductive aluminum. A single tracer, with the addition of QMax LITE, can achieve the same results as 2-3 tube tracers. This saves time and money on capital projects and reduces long-term maintenance cost.

Steam Tracing

FPX [Freeze Protection]

Specifications

| Model | QMax FPX |

| For Freeze Protection | <60°F (16°C) |

| Material | 6063-T5 Aluminum |

| Thermal Conductivity | ~1450 BTU/hr ft^2 °F (~209 W/m-°K) |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~0.08 lb/ft (without tubing) |

| Standard tube/pipe sizes | 3/8’’ & 1/2’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax FPX (Freeze Protection) is a continuous steam tracing standoff designed specifically for pipeline freeze protection. The QMax FPX innovative design mitigates the heat transfer of regular stainless steel or copper tube tracer and offers guaranteed results. Most steam tracing standoffs are poorly designed or not designed at all. Tubing often touches the pipe which creates hot spots that can lead to internal corrosion. QMax FPX continuous steam tracing standoff mitigates hot spots while offering predictable process temperatures. QMax Industries, Inc. models the thermal characteristics of each application so the results of the QMax FPX system are guaranteed. The profile of QMax FPX is customized to each application to ensure the best results.

Steam Tracing

CST [Freeze Protection]

Specifications

| Model | QMax CST

For Long-Run Hot Oil Tracing |

| Material | SA178 Grade A Boiler Tuber (Carbon Steel) |

| Thermal Conductivity | ~120 BTU/hr ft^2 °F |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~2.5 lb/ft (1.13 kg/m) (without tubing) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax CST (Carbon Steel Tracing) is a 1” x 2” rectangular pipe contoured on one side to match the outside diameter of the process pipe. Specifically designed for long-run hot oil tracing, QMax CST can be prefabricated from the customer drawings or it can be provided as parts and pieces to be fabricated in the field. In either case, QMax Industries, Inc. will provide a thermal analysis to size the system. QMax CST is formed from SA 178 Gr. A, carbon steel boiler tubing. The elements are fabricated and tested in accordance with ASME Boiler and Pressure Vessel Code, Section VIII, Div. 1 or Section IX.

Equipment Jacketing

FJH [Electric Heating Jacket]

Specifications

| Model | QMax FHJ |

| Body Material | A319 Cast Aluminum |

| Thermal Conductivity | ~754 BTU/hr ft^2 °F (~109 W/m-K) |

| Maximum Temperature | 750°F (399°C) |

| Cartridge Heater | {Varies} |

| Standard Rating | 600°F (315°C) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

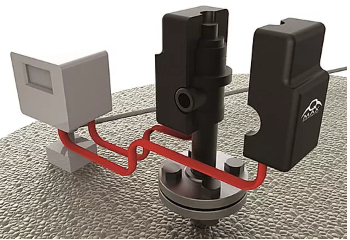

QMax Electric Heating Jackets are Custom made from aluminum and are designed to maintain specific process temperatures on process equipment such as flanges, nozzles, valves, pumps, meters, strainers and more. QMax EHJ’s house a removable electric cartridge heater that conducts heat through the aluminum to create a “heat shield” effect around the component. Use QMax EHJ’s in electric tracing applications instead of wrapping the valve with electric tracing.

Equipment Jacketing

QFX [Fabricated Jackets]

Specifications

| Model | QMax QFX |

| Jacket Material | Made to Order |

| Maximum Temperature | 900°F |

| Standard Rating | 150 psig at 600°F |

| Standard Connection Type | 1/2 ‘’ FNPT |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax FX (Fabricated Jackets) are custom components made from carbon or stainless steel to fit process equipment such as flanges, nozzles, valves, pumps, meters, strainers and more. QMax FX jackets are designed to create a “heat shield” effect around the component to eliminate freezing and cold spots around the equipment.

QMax FX Bolt-On Fabricated jackets are offered for most process piping equipment including fittings, valves, pumps, meters, and strainers. These jackets are all custom fabricated and made to order but can be produced very quickly. Carbon steel is our standard jacket material, but other materials are available such as stainless steel, titanium, and other exotic metals. Our QFX jackets have a large heating chamber which provides efficient temperature control over the total surface of the equipment.

QMax FX Weld-On Fabricated jackets are offered for equipment such as fittings, valves, and strainers. These jackets are custom fabricated and are welded directly to the process equipment. Like our Bolt-on option, various metals may be used. Consult with a QMax representative to get the best solution for your application.

Tank Heating

QFIN [Tank Heating System]

Specifications

| Model | QMax QFIN |

| Material | 6063-T5 Aluminum |

| Thermal Conductivity | ~1450 BTU/hr ft^2 °F (~209 W/m-K) |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~10 lb/ft |

| Standard internal coil sizes | Pipe = 2,3,4 inch CS pipe

Tubing = ¼, ½, ¾, inch tube |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QFin’s Design Maximizes the heat input of a carbon or stainless-steel internal heating coils and it is fully removable and replaceable. QFin is a bolt-on heating fin that attaches to any size pipe. The highly conductive aluminum material of QFin increases the heating surface area by 1,000% which allows for greater heating capabilities or decreased total footage of the internal coil. QFin is specifically designed for high-viscosity fluids such as Asphalt, Bitumen and Coker Feeds to allow for easy removal and reinstallation of fins if the product cokes on the fins.

Tank Heating

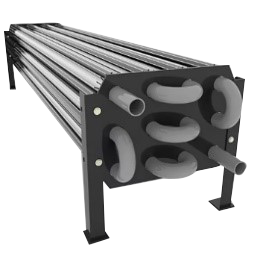

QCB [Standard Coil Bank]

Specifications

| Model | QMax QFIN |

| Material | 6063-T5 Aluminum |

| Thermal Conductivity | ~1450 BTU/hr ft^2 °F (~209 W/m-K) |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~10 lb/ft |

| Standard internal coil sizes | Pipe = 2,3,4 inch CS pipe

Tubing = ¼, ½, ¾, inch tube |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax Industries offers a wide variety of internal tank heating coil options including bare pipe coils and spiral welded finned tube coils. Our engineers often size and design custom heating coils to ensure we meet specific needs of the project. We also offer standard heating coil bank configurations for one-pick installation. QMax tank heating coils can be designed using several heating media including steam, hot oil, water or explosion-proof catalyst (by QMax Catalytic, LLC.) These coils can also be designed to fit into existing tank manway openings or into any specific tank or vessel.

Tank Heating

FTS [Fluid Tracing System]

Specifications

| Model | QMax QFIN |

| Material | 6063-T6 Aluminum |

| Thermal Conductivity | ~1390 BTU/hr ft^2 °F (~209 W/m-K) |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~0.55 lb/ft (.82 kg/m) |

| Standard tube/pipe Sizes | 3/8’’ thru 5/8’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax FTS Heat Tracing Maximizes the heat input of regular stainless steel or copper tube tracer and offers consistent results. First, QMax transforms the nature of a steam tracer from ineffective convective heat transfer to highly efficient conductive heat transfer. Second, the heating surface area is increased to as much as 2 inches (50mm) using highly conductive aluminum. When compared to traditional tracing on a vessel, the QMax FTS system can significantly reduce the number of tracing passes required. When compared with traditional plate coils, QMax FTS can offer much greater contact for more consistent tank heating results.

Tank Heating

CST [Carbon Steel Tracing]

Specifications

| Model | QMax CST |

| Material | SA178 Grade A Boiler Tube (carbon steel) |

| Thermal Conductivity | ~120 BTU/hr ft^2 °F |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~2.5 lb/ft (1.13 kg/m) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

QMax CST (Carbon Steel Tracing) is a 1” x 2” rectangular pipe contoured on one side to match the outside diameter of the process pipe. Specifically designed for long-run hot oil tracing, QMax CST can be prefabricated from customer drawings or it can be provided as parts and pieces to be fabricated in the field. In either case, QMax Industries, Inc. will provide a thermal analysis to size the system. QMax CST is formed from SA 178 Gr. A, carbon steel boiler tubing. The elements are fabricated and tested in accordance with ASME Boiler and Pressure Vessel Code, Section VIII, Div. 1 or Section IX.