Products

Liquid Drainers Back to all Liquid Drainers

- In this category:

- WLD1900 Series

- WLD1400 Series

- WLD600/WLD601 Series

- WLD1800 Series

- WLD1800R Series

- AVDT Series

- WLD1703S Series

- WLD1500 Series

- WLD1500 w/Strainer

- PN16/PN40

Float Type Liquid Drainer

WLD1900 Series

Specifications

| Model | WLD1900 |

| Sizes | 3/4’’, 1’’, 1-1/4’’, 1-1/2’’, 2’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WLD1900-Series Liquid Drainers have Cast Iron Bodies. Parallel Pipe Connection. 250 psig Operating Pressures. All Stainless-Steel Internals. Used for draining liquids from Tanks, Vessels, and piping systems containing pressurized Air or other gases.

Float Type Liquid Drainer

WLD1400 Series

Specifications

| Model | WLD1400 |

| Sizes | 1/2’’, 3/4’’, 1’’, 1-1/2’’, 2’’ |

| Connections | NPT |

| Body Material | Ductile Iron |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 300 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 300 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WLD1400-Series have ductile iron bodies, in-line pipe connections, 300 psig operating pressures, all stainless-steel internals. Used for draining liquids from Tanks, Vessels, and piping systems containing pressurized Air or other gases.

Float Type Liquid Drainer

WLD600/WLD601 Series

Specifications

| Model | WLD600 & WLD601 |

| Sizes | 3/4’’, 1’’, 1-1/2’’, 2’’, 3’’, 4’’ |

| Connections | NPT, SW, Flanged |

| Body Material (WLD600) | Carbon Steel |

| Body Material (WLD601) | 316 Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 990 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 670 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WLD600-Series have Cast Steel Bodies. The WLD601-Series have Stainless Steel Bodies. Used for draining liquids from Tanks, Vessels, and piping systems containing pressurized Air or other gases.

Guided Float Liquid Drainer

WLD1800 Series

Specifications

| Model | WLD1800 Non-repairable |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 400 PSIG |

| TMO (Max. Operating Temperature) | 500°F |

| PMA (Max. Allowable Pressure) | 400 PSIG @ 500°F |

| TMA (Max. Allowable Temperature) | 500°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WLD1800 Drainer contain a stainless-steel float and hardened stainless steel seat and disc to drain out liquids from pressurized pipelines, tank, and vessels without the loss of the pressured gas. Available in either a repairable (WLD1800R) or a non-repairable (WLD1800) version. The all stainless-steel construction allows them to be used in extremely corrosive environments. The WLD1800 is seal welded and therefore non-repairable.

Guided Float Liquid Drainer

WLD1800R Series

Specifications

| Model | WLD1800R Repairable |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 400 PSIG |

| TMO (Max. Operating Temperature) | 500°F |

| PMA (Max. Allowable Pressure) | 400 PSIG @ 500°F |

| TMA (Max. Allowable Temperature) | 500°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WLD1800R Drainer contain a stainless-steel float and hardened stainless steel seat and disc to drain out liquids from pressurized pipelines, tanks, and vessels without the loss of the pressured gas. Available in either a repairable (WLD1800R) or a non-repairable (WLD1800) version. The all stainless-steel construction allows them to be used in extremely corrosive environments. The WLD1800R can be disassembled for service and replacement of internal components.

Guided Float Liquid Drainer

AVDT Series

Specifications

| Model | AVDT-150, AVDT-300 |

| Sizes | 1/2’’ to 1” |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | AVDT-150 @ 150 PSIG |

| AVDT-300 @ 300 PSIG | |

| TMO (Max. Operating Temperature) | AVDT-150 @ 250°F |

| AVDT-300 @ 338°F | |

| PMA (Max. Allowable Pressure) | 150 PSIG @ 250°F

300 PSIG @ 338°F |

| TMA (Max. Allowable Temperature) | 250°F @ 150 PSIG

338°F @ 300 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The soft EPDM seating allows for bubble tight operation and eliminates the nuisance ‘spitting’ often associated with metal-to-metal seats.

The cover is fitted with a 1/2″ npt plugged connection. This can be fitted with a full-bore ball valve to allow for manual by-pass to decrease start-up time during system filling.

Thermodynamic Liquid Drainer

WLD1703S Series

Specifications

| Model | WLD1703S |

| Sizes | 1/2’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| Options | Blowdown Valve |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 915 PSIG up to 250°F |

| TMA (Max. Allowable Temperature) | 610°F @ 750 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

Thermodynamic Liquid Drainers (WLD1703S) are all stainless-steel construction with a built-in strainer and optional blow down valve. Integral seat design and disc to be hardened for long service life. Unit shall be capable of installation in any direction and does not require balancing lines.

Inverted Bucket Liquid Drainer

WLD1500 Series

Specifications

| Model | WLD1501, WLD1502, WLD1504, WLD1521, WLD1522, WLD1524 |

| Sizes | 3/4’’, 1’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WLD1500 Series Inverted Bucket Liquid Drain Traps are recommended for the removal of liquids from compressed air systems. A scrubber wire is used to keep bleed hole on top of inverted bucket from clogging due to oil that may be present in the water being drained. Oil mixed with water is typically found on compressed air systems.

Inverted Bucket Liquid Drainer

WLD1500 w/Strainer

Specifications

| Model | WLD1501, WLD1502, WLD1504, WLD1521, WLD1522, WLD1524 |

| Sizes | 3/4’’, 1’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WLD1500 Series Inverted Bucket Liquid Drain Traps are recommended for the removal of liquids from compressed air systems. A scrubber wire is used to keep bleed hole on top of inverted bucket from clogging due to oil that may be present in the water being drained. Oil mixed with water is typically found on compressed air systems.

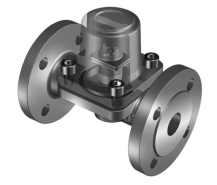

PN16/PN40

PN16/PN40

Specifications

| Model | PN16/PN40 |

| Sizes | 1/2’’ – 1’’ |

| Connections | FLG, BW |

| Body Material | EN-JL1040 or 1.0460 |

| Operating Pressure | Up to 464 PSIG |

| Inlet Temperature | Up to 842°F |

| Allow. Diff. pressure | 14,73 PSIG (Closing pressure, Factory setting) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The PN16/PN40 Automatic liquid drainer features automatic condensate discharge during start-up and shut down. On unpressurized systems the liquid drainer will be opened by a compression spring inside of the controller. On factory setting the liquid drainer will be closed at a differential pressure of ≥22 PSIG. Other factory settings between 7 PSIG and 29 PSIG are possible. Bimetallic elements will achieve that the closing pressure is constant. Installation in any position (if a frost resistant execution is required please inquire)