Products

Heat Tracing Back to all Heat Tracing

- In this category:

- FTS [Fluid Steam Tracing]

- LITE [Light Steam Tracing]

- FPX [Freeze Protection]

- CST [Freeze Protection]

Steam Tracing

FTS [Fluid Steam Tracing]

Specifications

| Model | QMax FTS Gen 2 |

| For Critical Heat Applications | >180°F (82°C) |

| Material | 6063-T6 Aluminum |

| Thermal Conductivity | ~1390 BTU/hr ft^2 °F (~209 W/m-°K) |

| Max. Temperature Limitation | 750°F (399°C) |

| Weight | ~0.60 lb/ft (0.82 kg/m) |

| Standard tube/pipe size | 3/8’’ – 5/8’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

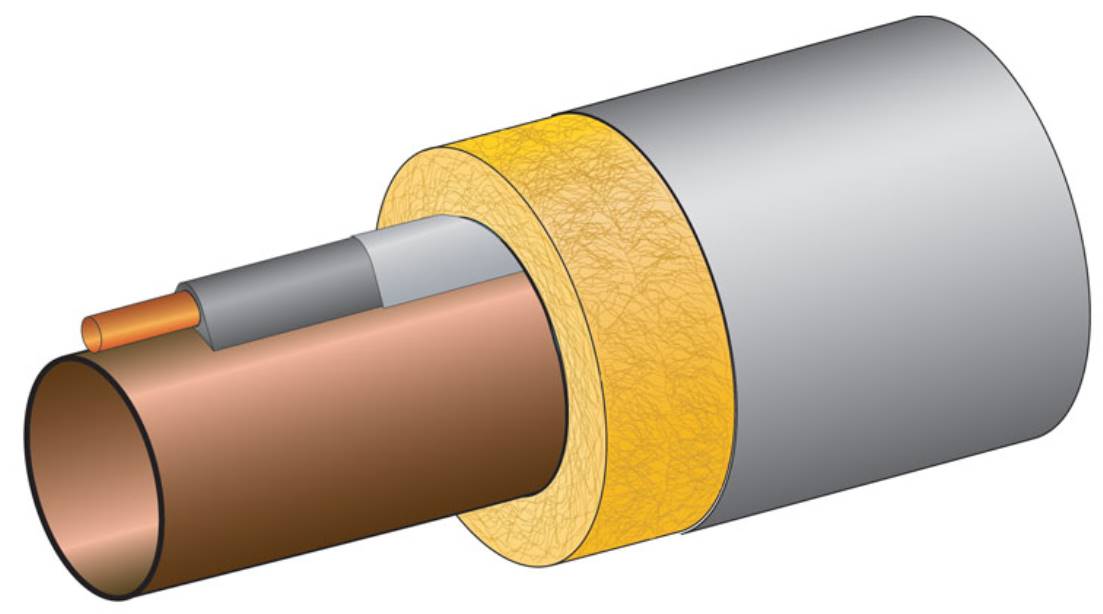

QMax FTS Gen 2 heat tracing maximizes the heat input of regular stainless steel or copper tube tracer and offers consistent results. First, QMax transforms the nature of a steam tracer from ineffective convective heat transfer to highly efficient conductive heat transfer. Second, the heating surface area is increased to as much as 2 inches (50mm) using highly conductive aluminum. A single tracer with the addition of QMax FTS can achieve the same results as multiple tube tracers or even jacketed pipe. This saves time and money on capital projects and reduces long-term maintenance costs.

Steam Tracing

LITE [Light Steam Tracing]

Specifications

| Model | QMax Lite |

| For Medium Heat Applications | 60°F – 180°F (16°C – 82°C) |

| Material | 6063-T6 Aluminum |

| Thermal Conductivity | ~1390 BTU/hr ft^2 °F (~209 W/m-°K) |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~0.60 lb/ft (0.82 kg/m) (without tubing) |

| Standard tube/pipe sizes | 3/8’’ – 5/8’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The QMax Lite Heat Tracing design maximizes the heat input of regular stainless steel or copper tube tracer and offers guaranteed results. QMax LITE is designed for light-duty steam tracing and most glycol tracing applications. QMax LITE transforms the nature of the tracer from inefficient convective heat transfer to high-efficiency conductive heat transfer. The heating surface area is increased to as much as 1.5 inches (38mm) using highly conductive aluminum. A single tracer, with the addition of QMax LITE, can achieve the same results as 2-3 tube tracers. This saves time and money on capital projects and reduces long-term maintenance cost.

Steam Tracing

FPX [Freeze Protection]

Specifications

| Model | QMax FPX |

| For Freeze Protection | <60°F (16°C) |

| Material | 6063-T5 Aluminum |

| Thermal Conductivity | ~1450 BTU/hr ft^2 °F (~209 W/m-°K) |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~0.08 lb/ft (without tubing) |

| Standard tube/pipe sizes | 3/8’’ & 1/2’’ |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

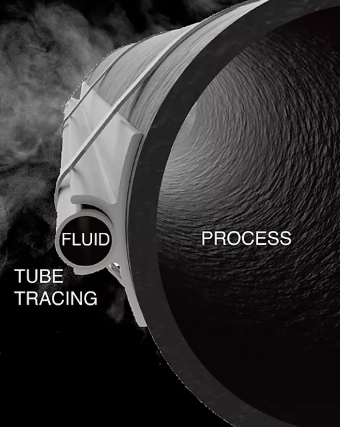

QMax FPX (Freeze Protection) is a continuous steam tracing standoff designed specifically for pipeline freeze protection. The QMax FPX innovative design mitigates the heat transfer of regular stainless steel or copper tube tracer and offers guaranteed results. Most steam tracing standoffs are poorly designed or not designed at all. Tubing often touches the pipe which creates hot spots that can lead to internal corrosion. QMax FPX continuous steam tracing standoff mitigates hot spots while offering predictable process temperatures. QMax Industries, Inc. models the thermal characteristics of each application so the results of the QMax FPX system are guaranteed. The profile of QMax FPX is customized to each application to ensure the best results.

Steam Tracing

CST [Freeze Protection]

Specifications

| Model | QMax CST

For Long-Run Hot Oil Tracing |

| Material | SA178 Grade A Boiler Tuber (Carbon Steel) |

| Thermal Conductivity | ~120 BTU/hr ft^2 °F |

| Maximum Temperature Limitation | 750°F (399°C) |

| Weight | ~2.5 lb/ft (1.13 kg/m) (without tubing) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

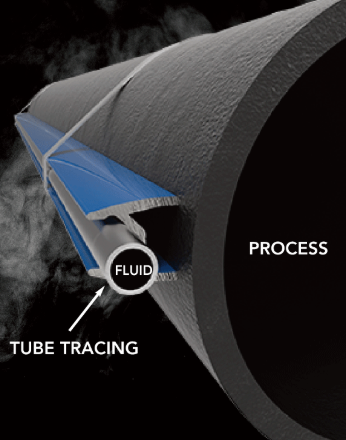

QMax CST (Carbon Steel Tracing) is a 1” x 2” rectangular pipe contoured on one side to match the outside diameter of the process pipe. Specifically designed for long-run hot oil tracing, QMax CST can be prefabricated from the customer drawings or it can be provided as parts and pieces to be fabricated in the field. In either case, QMax Industries, Inc. will provide a thermal analysis to size the system. QMax CST is formed from SA 178 Gr. A, carbon steel boiler tubing. The elements are fabricated and tested in accordance with ASME Boiler and Pressure Vessel Code, Section VIII, Div. 1 or Section IX.