Products

Steam Traps Back to all Steam Traps

- In this category:

- TD600

- TD600S

- TD700S

- TD900S

- TD3600

- WT1000

- WT2000

- WT2500

- WT3000

- WT4000

- WT5000

- FT

- FTT

- FTTS

- FTE

- FTES

- FT600

- FT601

- WFT

- IB Series

- IB Series w/Strainer

- SIB/SIBH Series

- UT450

- UTD450

- UTD450SM/UTD600LSM

- UFT450

- USIB450

- UB450

- WPN-40

- WPN-63

- WPN-100

- WPN-160

- WPN-250

- FM

- CCM

- TA25B

- TA125

- TS25B

- TS125

- Test Valve

- SDM

- UTS600

- UC450

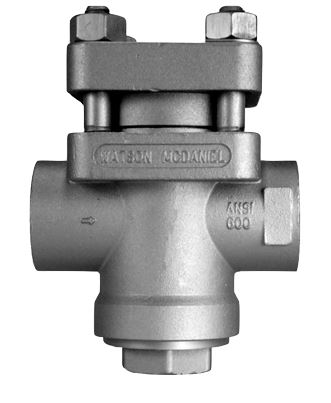

Thermodynamic Steam Trap

TD600

Specifications

| Model | TD600, TD600L |

| Sizes | 3/8’’, 1/2’’, 3/4’’, 1’’ |

| Connections | NPT |

| Body Material | Stainless Steel 420F |

| Options | Insulation C |

| PMO Max. Operating Pressure | 600 PSIG |

| TMO Max. Operating Temperature | 800°F |

| PMA Max. Allowable Pressure | 600 PSIG up to 800°F |

| TMA Max. Allowable Temperature | 800°F @ 600 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TD600 is Non-Repairable and commonly used as a drip trap on steam mains and steam supply lines. Ideal for outdoor applications that are subject to freezing and for super-heated steam conditions. The TD600L is Reduced Size Discharge Orifice holes which are preferable in terms of performance, longevity, and efficiency; particularly on pressure over 150 psi.

Thermodynamic Steam Trap

TD600S

Specifications

| Model | TD600S, TD600LS |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | NPT |

| Body Material | Stainless Steel 420F |

| Options | Blowdown Valve, Insulation Cap |

| PMO (Max. Operating Pressure) | 600 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 915 PSIG up to 250°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TD600S is Non-Repairable and commonly used as a drip trap on steam mains and steam supply lines. Supplied with integral strainer and optional blowdown valve to protect trap from contamination. Ideal for outdoor applications that are subject to freezing and for super-heated steam conditions. The TD600LS is Reduced Size Discharge Orifice holes which are preferable in terms of performance, longevity, and efficiency; particularly on pressure over 150 psi.

Thermodynamic Steam Trap

TD700S

Specifications

| Model | TD700S, TD700HS |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | NPT, SW, FLG |

| Body Material | Chrome-Moly Allow Steel |

| Options | Blowdown Valve, Insulation Cap |

| PMO (Max. Operating Pressure) | 600 PSIG |

| TMO (Max. Operating Temperature) | 800°F |

| PMA (Max. Allowable Pressure) | 600 PSIG up to 800°F |

| TMA (Max. Allowable Temperature) | 800°F @ 600 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TD700S Thermodynamic steam trap is commonly used as a drip trap on steam mains and steam supply lines. These traps are used on tracing applications; however, thermostatic traps are normally recommended for this service. Supplied with an integral strainer and optional blow down valve to protect the trap from contamination. The internal working mechanism of the TD700S can be completely replaced while the trap body remains in line. Ideal for outdoor applications that are subject to freezing and for super-heated steam conditions.

Thermodynamic Steam Trap

TD900S

Specifications

| Model | TD900S, TD900LS |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | NPT, SW, 600# FLG |

| Body Material | Low Carbon Chrome-Moly |

| Options | Insulation Cap |

| PMO (Max. Operating Pressure) | 900 PSIG |

| TMO (Max. Operating Temperature) | 842°F |

| PMA (Max. Allowable Pressure) | 1500 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 842°F @ 981 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TD900S Thermodynamic steam trap is primarily used as a drip trap on high pressure steam mains and steam supply lines when a repairable trap type is desired. Ideal for outdoor applications that are subject to freezing and for super-heated steam conditions. The TD900LS is recommended for pressure over 300 PSI.

Thermodynamic Steam Trap

TD3600

Specifications

| Model | TD3600 |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | BW, SW, 600# FLG, 1500# FLG |

| Body Material | Forged Alloy Steel |

| PMO (Max. Operating Pressure) | 3600 PSIG |

| TMO (Max. Operating Temperature) | 975°F @ 3600 psi

1025°F @ 2220 psi |

| PMA (Max. Allowable Pressure) | 2220 PSIG @ 1025°F

3600 PSIG @ 975°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TD3600 Thermodynamic steam trap is commonly used as a drip trap on high-pressure steam mains and steam supply lines. Supplied with an integral strainer to protect the trap from contamination. The internal working mechanism of the TD3600 can be completely replaced while the trap body remains in line. Ideal for outdoor applications that are subject to freezing and for super-heated steam conditions.

Thermostatic Steam Trap

WT1000

Specifications

| Model | WT1000 |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 1032 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 800 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT1000 thermostatic steam trap was specifically designed for drip and tracing applications as well as an air vent for heat exchangers. Like all thermostatic traps, the WT1000 is small, light, and has excellent air handling capabilities. The discharging of air on start-up allows steam to enter the system more quickly.

Thermostatic Steam Trap

WT2000

Specifications

| Model | WT2000 (Non-Repairable) |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 650 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 1032 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 800 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT2000* thermostatic steam trap is used for drip, tracing, and process applications. Their compact size, all stainless-steel construction, excellent air & handling capabilities, and the ability to operate over a wide & pressure range make them a good choice for most applications. They can also be used as an air vent on heat exchangers. Thermostatic traps are far superior to bucket traps and thermodynamic traps in their ability to remove air from the system. The discharging of air on startup allows steam to enter the system more quickly.

*WT2001 refer to 3/16″ orifice size and should be used on all drip and tracing applications, WT2003 refer to 5/16″ orifice size.

Thermostatic Steam Trap

WT2500

Specifications

| Model | WT2500 (Repairable) |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | 406°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT2500* thermostatic steam trap is used for drip, tracing and process applications. Their compact size, excellent air handling capability and wide operating pressure range make them a great choice for most applications. Thermostatic traps are far superior to bucket traps and thermodynamic disc traps in their ability to remove air from the system.

* WT2501 refer to 3/16″ orifice size, WT2503 refer to 5/16″ orifice size.

Thermostatic Steam Trap

WT3000

Specifications

| Model | WT3000 (Repairable) |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT, SW, FLG |

| Body Material | Stainless Steel |

| Options | Strainer, Blowdown Valve |

| PMO (Max. Operating Pressure) | 650 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 906 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 725 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT3000* thermostatic steam trap is used for industrial process applications. Their compact size, all stainless-steel construction, excellent air handling capability and wide operating pressure range make them a great choice for most process applications. Thermostatic traps are far superior to bucket traps and thermodynamic disc traps in their ability to remove air from the system.

* WT3001 refer to 3/16″ orifice size, WT3003 refer to 5/16″ orifice size.

Thermostatic Steam Trap

WT4000

Specifications

| Model | WT4000 (Repairable) |

| Sizes | 3/4’’, 1’’ |

| Connections | NPT, SW, FLG |

| Body Material | Stainless Steel |

| Options | Strainer, Blowdown Valve |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 906 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 725 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT4000* thermostatic steam trap is used for industrial process applications. Their compact size, all stainless-steel construction, excellent air handling capability and wide operating pressure range make them a great choice for most process applications. Thermostatic traps are far superior to bucket traps and thermodynamic disc traps in their ability to remove air from the system.

* WT4001 refer to 5/16″ orifice size, WT4003 refer to 7/16″ orifice size.

Thermostatic Steam Trap

WT5000

Specifications

| Model | WT5000 (Bi-Metal) |

| Sizes | 3/8’’, 1/2’’, 3/4’’, 1’’ |

| Connections | NPT, SW |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 650 PSIG |

| TMO (Max. Operating Temperature) | 662°F |

| PMA (Max. Allowable Pressure) | 900 PSIG |

| TMA (Max. Allowable Temperature) | 800°F |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT5000 Series Bi-metal Steam Trap is used in steam tracing applications (process lines, instrumentation and winterization, general steam jacketing) and small process applications where accurate control of condensate discharge temperature is required to utilize the sensible heat of the condensate.

Float & Thermostatic Steam Trap

FT

Specifications

| Model | FT Series |

| Sizes | 3/4’’, 1’’, 1-1/4’’, 1-1/2’’, 2’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 75 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 75 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 75 PSIG |

| Max Capacity | 12,500 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FT-Series Float and Thermostatic Steam Traps have Cast Iron Bodies, H-Pattern Piping Connections, 75 psig Operating Pressures, and Stainless-Steel Internals. Typically used on lower pressure HVAC and light industrial steam process applications such as unit heaters, pressing machines, heat exchangers, steam coils. Contain a welded stainless-steel thermostatic air vent for rapid air removal on system start-up. The dual inlet-outlet H-Pattern connection allows for additional flexibility in installation.

Float & Thermostatic Steam Trap

FTT

Specifications

| Model | FTT Series |

| Sizes | 1/2’’, 3/4’’, 1’’, 1-1/2’’, 2’’ |

| Connections | NPT, 150# FLG (1’’-2’’) |

| Body Material | Ductile Iron |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 300 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 300 PSIG |

| Max Capacity | 61,300 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FTT-Series Float and Thermostatic Steam Traps have Ductile Iron Bodies, In-Line Pipe Connections, 300 psig Operating Pressures, and All stainless-steel Internals. Typically used on steam process applications such as unit heaters, pressing machines, heat exchangers, steam coils. Contain a welded stainless-steel thermostatic air vent for rapid air removal on system start-up, important on process applications.

Float & Thermostatic Steam Trap

FTTS

Specifications

| Model | FTTS Series |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | NPT, SW |

| Body Material | CF8M Stainless Steel |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 300 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 300 PSIG |

| Max Capacity | 5,825 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FTTS-Series Float and Thermostatic Steam Traps have Stainless Steel Bodies, All Stainless-Steel Internals, and 225 psig Operating Pressures. These Steam traps are used where frequent System wash down is required or when rust and other surface corrosion cannot be tolerated such as in facilities used for Food and Beverage or Pharmaceutical production.

Float & Thermostatic Steam Trap

FTE

Specifications

| Model | FTE Series |

| Sizes | 1-1/2’’, 2’’, 2-1/2’’ |

| Connections | NPT |

| Body Material | Ductile Iron |

| PMO (Max. Operating Pressure) | 200 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 300 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 300 PSIG |

| Max Capacity | 105,000 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FTE-Series have Ductile Iron Bodies. Float and Thermostatic Steam Traps are intended for use on steam process applications with very high condensate load requirements. Examples include re-boilers, absorption chillers, large air-handling equipment and heat exchangers. They contain a high quality welded stainless-steel thermostatic air vent and all stainless internals. F&T traps have excellent air-handling capability, making them the preferred choice for most process applications.

Float & Thermostatic Steam Trap

FTES

Specifications

| Model | FTES Series |

| Sizes | 2-1/2’’ |

| Connections | NPT, SW, FLG |

| Body Material | Cast Steel |

| PMO (Max. Operating Pressure) | 300 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 300 PSIG up to 750°F |

| TMA (Max. Allowable Temperature) | 750°F @ 300 PSIG |

| Max Capacity | 105,000 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FTES-Series have Cast Steel Bodies. Float and Thermostatic Steam Traps are intended for use on steam process applications with very high condensate load requirements. Examples include re-boilers, absorption chillers, large air-handling equipment and heat exchangers. They contain a high quality welded stainless-steel thermostatic air vent and all stainless internals. F&T traps have excellent air-handling capability, making them the preferred choice for most process applications.

Float & Thermostatic Steam Trap

FT600

Specifications

| Model | FT600 Cast Steel Bodies |

| Sizes | 3/4’’, 1’’, 1-1/2’’, 2’’, 3’’, 4’’ |

| Connections | NPT, SW, FLG |

| Body Material | Carbon Steel |

| Options | Live Orifice Air Vent |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 990 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 670 PSIG |

| Max Capacity | 61,250 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FT600-Series have Cast Steel Bodies, Stainless Steel Internals, 450 psig Operating Pressures and intended for applications with Higher Pressures or where Steel Bodies are specified. Traps with Steel Bodies are often required in chemical plants and petrochemical refineries and used on re-boilers, heat exchangers, and other process applications.

Float & Thermostatic Steam Trap

FT601

Specifications

| Model | FT601 Stainless Steel Bodies |

| Sizes | 3/4’’, 1’’, 1-1/2’’, 2’’, 3’’, 4’’ |

| Connections | NPT, SW, FLG |

| Body Material | 316SS |

| Options | Live Orifice Air Vent |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 990 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 670 PSIG |

| Max Capacity | 61,250 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

FT601-Series have Stainless Steel Bodies, Stainless Steel Internals, 450 psig Operating Pressures and intended for applications with Higher Pressures or where Steel Bodies are specified. Traps with Steel Bodies are often required in chemical plants and petrochemical refineries and used on re-boilers, heat exchangers, and other process applications.

Float & Thermostatic Steam Trap

WFT

Specifications

| Model | WFT Series |

| Sizes | 3/4’’, 1’’, 1-1/4’’, 1-1/2’’, 2’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Temperature |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

| Max Capacity | 11,000 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The WT5000 Series Bi-metal Steam Trap is used in steam tracing applications (process lines, instrumentation and winterization, general steam jacketing) and small process applications where accurate control of condensate discharge temperature is required to utilize the sensible heat of the condensate.

Inverted Bucket Traps

IB Series

Specifications

| Model | 1031, 1032, 1033, 1034 |

| Sizes | 1/2’’, 3/4’’, 1’’, 1-1/4’’, 1-1/2’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| Options | Internal check Valve, Thermic Vent |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

| Max Capacity | 4,400 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The IB1030 Series inverted bucket stream trap are used in drip application to remove condensate from steam mains and steam supply lines, For drip application, the smaller sized units have an adequate capacity. The discharge orifice of the inverted bucket trap is mounted at the top of the trap body which makes them less susceptible to clogging from dirt and debris when compared to other trap types. Since IB traps have poor air-handling capacity, they are only recommended for process applications such as united heaters and laundry equipment, where discharging air during system start-up is not a critical factor. F&T traps are the preferred choice for systems where air MUST be quickly discharged.

Inverted Bucket Traps

IB Series w/Strainer

Specifications

| Model | 1041, 1042, 1044, 1038S |

| Sizes | 1/2’’, 3/4’’, 1’’, 1-1/4’’, 1-1/2’’ |

| Connections | NPT |

| Body Material | Cast Iron |

| Options | Internal check Valve, Thermic Vent |

| PMO (Max. Operating Pressure) | 250 PSIG |

| TMO (Max. Operating Temperature) | 450°F |

| PMA (Max. Allowable Pressure) | 250 PSIG up to 450°F |

| TMA (Max. Allowable Temperature) | 450°F @ 250 PSIG |

| Max Capacity | 5,500 lbs/hr |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The IB1040 Series with built-in strainer and blowdown valve connection are used in drip application to remove condensate from steam mains and steam supply lines, for drip application, the smaller sized units have an adequate capacity. The discharge orifice of the inverted bucket trap is mounted at the top of the trap body which makes them less susceptible to clogging from dirt and debris when compared to other trap types. Since IB traps have poor air-handling capacity, they are only recommended for process applications such as united heaters and laundry equipment, where discharging air during system start-up is not a critical factor. F&T traps are the preferred choice for systems where air MUST be quickly discharged.

Inverted Bucket Traps

SIB/SIBH Series

Specifications

| Model | SIB, SIBH |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT, SW |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 750°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The SIB & SIBH traps are suitable for removing condensate from steam mains and steam supply lines. They are also used on unite heaters, low capacity and less critical process applications where slow start-up can be tolerated. The discharge orifice of the inverted bucket trap is mounted at the top of the trap body, which makes them less susceptible to clogging from dirt and debris when compared to other trap types. The SIBH is physically larger and has a higher-pressure capability for a particular orifice size then SIB.

Universal Thermostatic Steam Trap Module

UT450

Specifications

| Model | UT450 |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | Saturated Steam Steel |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The UT450 Thermostatic Steam Trap Module can be used anywhere conventional thermostatic steam traps are used. Used for drip, tracing and light process applications. Trap module mounts to any 2-bolt Quick-Change Universal Connector.

Universal Thermodynamic Steam Trap Module

UTD450

Specifications

| Model | UTD450, UTD450L |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

Designed to work as a drip trap for the draining of condensate from steam mains and other steam supply lines, the UTD450 Thermodynamic Steam Trap Module can be used anywhere conventional thermodynamic steam traps are used. Can also be used on tracing applications. This model is only recommended for horizontal piping installations to allow the cap to be oriented upwards. The UTD450 mounts to any 2-bolt Quick-Change Universal Connector.

The UTD450 is recommended for horizontal piping only so that cap can be oriented upwards, as shown.

Universal Thermodynamic Steam Trap Module

UTD450SM/UTD600LSM

Specifications

| Model | UTD450LSM, UTD450SM, UTD600LSM |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG (For UTD450SM) |

| PMO (Max. Operating Pressure) | 600 PSIG (For UTD600LSM) |

| TMO (Max. Operating Temperature) | 750°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG (For UTD450SM) |

| TMA (Max. Allowable Temperature) | 800°F @ 600 PSIG (For UTD600LSM) |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

Designed for drip applications for the draining of condensate from steam mains and other steam supply lines as well as for tracing applications. The UTD450 & UTD600 Steam Trap Modules can be used anywhere conventional thermodynamic steam traps are used. This trap module can be used on either vertical or horizontal piping installations and can mount to any 2-bolt Quick-Change Universal Connector.

Universal Float & Thermostatic Steam Trap Module

UFT450

Specifications

| Model | UFT450 |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 225 PSIG |

| TMO (Max. Operating Temperature) | 397°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The UFT450 Float & Thermostatic steam trap module can be used on small process equipment which generate light condensate loads. F&T traps have excellent air handling capability. These F&T trap modules can also be used in drip service on steam mains and steam supply lines. Mounts to any Universal Connector.

Universal Inverted Bucket Steam Trap Module

USIB450

Specifications

| Model | USIB450, USIB450H |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 800°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The USIB450 inverted bucket steam trap modules must be mounted to a Universal Connector. They are typically used for drip applications such as draining condensate from steam mains or steam supply lines as well as for steam tracing applications. USIB450H is the higher capacity model.

All USIB450 modules mounts to any 2-bolt Quick-Change Universal Connector. Please refer to the Universal Connector product page.

Universal Bi-Metallic Steam Trap Module

UB450

Specifications

| Model | UB450 |

| Connections | Fits UC450 Series Universal Connectors |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | 450 PSIG |

| TMO (Max. Operating Temperature) | 662°F |

| PMA (Max. Allowable Pressure) | 720 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The UB450 steam trap module are used in steam tracing applications (from process line heating, instrumentation and winterization, general steam jacketing). In tracing applications, the externally – adjustable (temperature adjustment) bi-metal element provides accurate control of condensate discharge temperature as required to maintain a specific product temperature as well provide maximum usage of energy.

The UB450 trap module mounts to any Universal Connector. Please refer to the Universal Connector product page.

Bi-Metallic Steam Trap

WPN-40

Specifications

| Model | WPN-40 |

| Sizes | 1/2’’, 3/4’’, 1’’, 2’’ |

| Connections | NPT, SW, BW, FLG |

| Body Material | Hardened SST (55Rc) |

| PMO (Max. Operating Pressure) | 319 PSIG |

| Pressure Controller | 320 psig up to 460 psig |

| Max Diff. Pressure (PSI) | 320 psi up to 460 psi |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPN-40 series are available in sizes 1/2″ – 2″ and pressure up to 470 psig. They offer 2 different pressure controllers; max diff. pressure up to 320psi (R22) and up to 460psi (R32), respectively. They are extremely robust and reliable, making them a suitable choice for superheated steam, high pressure applications, as well as outdoor applications that are subject to freezing

Bi-Metallic Steam Trap

WPN-63

Specifications

| Model | WPN-63 |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | SW, BW, FLG |

| Body Material | Hardened SST (55Rc) |

| PMO (Max. Operating Pressure) | 823 PSIG |

| Pressure Controller | 823 psig |

| Max Diff. Pressure (PSI) | 810 psi |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPN-63 series are available in sizes 1/2″ – 1″ and pressure up to 823 psig. Also, the max diff. pressure up to 810 psi. They are extremely robust and reliable, making them a suitable choice for superheated steam, high pressure applications, as well as outdoor applications that are subject to freezing.

Bi-Metallic Steam Trap

WPN-100

Specifications

| Model | WPN-100 |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | SW, BW, FLG |

| Body Material | Hardened SST (55Rc) |

| PMO (Max. Operating Pressure) | 1220 PSIG |

| Pressure Controller | 1305 psig |

| Max Diff. Pressure (PSI) | 1200 psi |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPN-100 series are available in sizes 1/2″ – 1″ and pressure up to 1220 psig. Also, the max diff. pressure up to 1200 psi. They are extremely robust and reliable, making them a suitable choice for superheated steam, high pressure applications, as well as outdoor applications that are subject to freezing.

Bi-Metallic Steam Trap

WPN-160

Specifications

| Model | WPN-160 |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | SW, BW, FLG |

| Body Material | Hardened SST (55Rc) |

| PMO (Max. Operating Pressure) | 1620 PSIG |

| Pressure Controller | 1595 psig |

| Max Diff. Pressure (PSI) | 1600 psi |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPN-160 series are available in sizes 1/2″ – 1″ and pressure up to 1620 psig. Also, the max diff. pressure up to 1600 psi. They are extremely robust and reliable, making them a suitable choice for superheated steam, high pressure applications, as well as outdoor applications that are subject to freezing.

Bi-Metallic Steam Trap

WPN-250

Specifications

| Model | WPN-250 |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | SW, BW, FLG |

| Body Material | Hardened SST (55Rc) |

| PMO (Max. Operating Pressure) | 2260 PSIG |

| Pressure Controller | 2233 psig |

| Max Diff. Pressure (PSI) | 2230 psi |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

WPN-250 series are available in sizes 1/2″ – 1″ and pressure up to 2260 psig. Also, the max diff. pressure up to 2230 psi. They are extremely robust and reliable, making them a suitable choice for superheated steam, high pressure applications, as well as outdoor applications that are subject to freezing.

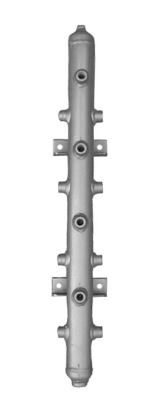

Steel Manifold

FM

Specifications

| Model | FM |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT, SW |

| Body Material | Carbon Steel |

| PMO (Max. Operating Pressure) | 720 PSIG |

| # of Branches | 4, 6, 8, 12 |

| Manifold Type | Collection, Distribution |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The FM Manifold is equipped with threaded or socket welded mount holes for ease of installation. Condensate collection manifolds are provided with a built-in siphon tube to minimize bi-phase flow, which reduces water hammer, and allows flash steam space to prevent isolation station freeze damage.

Condensate Collection Manifold

CCM

Specifications

| Model | CCM |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT, SW, Other |

| Body Material | Forged Carbon Steel |

| PMO (Max. Operating Pressure) | 600 PSIG |

| Pressure/Temp. Rating | 600 PSIG @ 825F |

| Number of Branches | 4, 6, 8, 10, 12 |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The CCM Series manifold is forged carbon steel with 4, 6, 8, 10 or 12 branch condensate inlet connections. Available with a variety of end connections, including NPT or Socket-weld. The top condensate outlet connection is either NPT, Butt-weld or Flanged. The bottom drain connection is available with optional gate valve. The manifold assembly is offered separately or with optional frame stand. Model CCMS condensate collection manifold is provided with a built-in siphon tube to minimize bi-phase flow, which reduces water-hammer and helps control flash steam. Available with integral isolation valves.

Radiator Steam Trap

TA25B

Specifications

| Model | TA25B |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Forged Brass, CA 377 |

| PMO (Max. Operating Pressure) | 25 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TA25B Series Radiator Trap with Right Angle Connection are Thermostatic Steam Traps that were specifically designed for removing condensate and air from 2-pipe steam heating systems. The bodies are made from a high-quality brass forging and can be fully repaired while the product remains in-line by removing the cap and easily replacing the seat and thermal element. It is available in 1/2″ & 3/4″ NPT connections with pressure ranges: 25 PSIG.

Radiator Steam Trap

TA125

Specifications

| Model | TA125 |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Forged Brass, CA 377 |

| PMO (Max. Operating Pressure) | 125 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TA125 Series Radiator Traps with Right Angle Connection are Thermostatic Steam Traps that were specifically designed for removing condensate and air from 2-pipe steam heating systems. The bodies are made from a high-quality brass forging and can be fully repaired while the product remains in-line by removing the cap and easily replacing the seat and thermal element. It is available in 1/2″ & 3/4″ NPT connections with pressure ranges: 125 PSIG.

Radiator Steam Trap

TS25B

Specifications

| Model | TS25B |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Forged Brass, CA 377 |

| PMO (Max. Operating Pressure) | 25 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TS25B Series Radiator Trap with Straight-thru (in-line) connection are Thermostatic Steam Traps that were specifically designed for removing condensate and air from 2-pipe steam heating systems. The bodies are made from a high-quality brass forging and can be fully repaired while the product remains in-line by removing the cap and easily replacing the seat and thermal element. It is available in 1/2″ & 3/4″ NPT connections with pressure ranges: 25 PSIG.

Radiator Steam Trap

TS125

Specifications

| Model | TS125 |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT |

| Body Material | Forged Brass, CA 377 |

| PMO (Max. Operating Pressure) | 125 PSIG |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The TS125 Series Radiator Trap with Straight-thru (in-line) connection are Thermostatic Steam Traps that were specifically designed for removing condensate and air from 2-pipe steam heating systems. The bodies are made from a high-quality brass forging and can be fully repaired while the product remains in-line by removing the cap and easily replacing the seat and thermal element. It is available in 1/2″ & 3/4″ NPT connections with pressure ranges: 125 PSIG.

Steam Trap Accessory

Test Valve

Specifications

| Model | WSTTV |

| Sizes | 1/2’’, 3/4’’, 1’’ |

| Connections | NPT |

| Body Material | Stainless Steel |

| Working Steam Pressure | 150 PSIG WSP |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

The Steam Trap Test Valve offers simple, immediate, and visible diagnosis of any steam trap. Turning the handle 90 °to the “Test” position will direct flow of steam trap out the test port for visual evaluation of discharge.

Test Valves can be installed downstream of any steam strap to visually inspect the discharge of condensate from the traps. Available in stainless steel up to 1″ in size.

Steam Distribution Manifold

SDM

Specifications

| Model | SDM |

| Sizes | 1/2’’, 3/4’’ |

| Connections | NPT, SW, Other |

| Body Material | Forged Carbon Steel |

| PMO (Max. Operating Pressure) | 600 PSIG |

| Pressure/Temp. Rating | 600 PSIG @ 825F |

| Number of Branches | 4, 8, 12 |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

SDM Series are used for steam distribution TO the tracing system. Commonly used in chemical and petrochemical facilities as well as in other industrial plants that have multiple tracing applications. Manifolding the steam distribution system not only reduces installation and maintenance costs, but also streamlines and organizes piping. The SDM Series has integral isolation valves (option available without isolation valves).

The SDM Series manifold is forged carbon steel with 4, 8 or 12 branch steam outlet connections with integral isolation valves. Available with a variety of end connections, including NPT or Socket-weld. The top steam inlet connection is either Butt-weld or Flanged. The bottom condensate outlet connection is available with optional gate valve. The manifold assembly is offered separately or with optional frame stand.

UTS600

UTS600

Specifications

| Model | UTS600 |

| Sizes: | ½”, ¾”, 1” |

| Connections | NPT,SW,FLG |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | (trap module dependent) |

| TMO (Max. Operating Temperature) | (trap module dependent) |

| PMA (Max. Allowable Pressure) | 1440 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 845 PSIG |

| Can be Used with: | USIB450, UTD450, UTD450SM, UTD450LSM, UT450, UFT450, UB450 |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

UTS600 Series Universal Connector Trap Test Valve Stations reduce the time and manpower to test and replace steam traps. The stainless steel Connector remains permanently in-line allowing steam trap module to be replaced in minutes. Integral isolation valves and trap test valve allow for simple trap testing to determine operation. These universal connectors can be used for drip service on steam mains and steam supply lines, tracing, or for small process equipment. Industrial standard 2-bolt universal connectors are commonly used in chemical plants, petrochemical refineries, paper mills, and other industrial facilities. The UTS600 connectors conform to industrial standards, making them compatible with other manufacturers’ universal steam trap modules.

Universal Connectors

UC450

Specifications

| Model | UC450, UC450S, UC450SB, UC4500SR, UC450SBR, UC450SL, UC450SBL |

| Sizes: | ½”, ¾”, 1” |

| Connections | NPT, SW, FLG |

| Body Material | Stainless Steel |

| PMO (Max. Operating Pressure) | (trap module dependent) |

| TMO (Max. Operating Temperature) | (trap module dependent) |

| PMA (Max. Allowable Pressure) | 750 PSIG @ 100°F |

| TMA (Max. Allowable Temperature) | 800°F @ 400 PSIG |

| Can be Used with: | USIB450, UTD450, UTD450SM, UTD450LSM, UT450, UFT450, UB450 |

Contact Us for more information on this product and to see other sizes that fit unique applications.

Typical Applications

Universal connectors remain permanently installed in the piping system. The convenient 2-bolt mounting system allows the trap module to be removed and replaced quickly and easily using a socket or open-end wrench without disturbing the existing piping. These universal connectors can be used for drip service on steam mains and steam supply lines, tracing, or for small process equipment. Industrial standard 2-bolt universal connectors are commonly used in chemical plants, petrochemical refineries, paper mills, and other industrial facilities. The UC450 connectors conform to industrial standards, making them compatible with other manufacturers’ universal steam trap modules.